Looking for the key differences between Inventory Management Vs Warehouse management? From listing products and marketing, down to fulfilment and shipping, there’s a web of responsibilities that come with running a store.

Although often interconnected, it is also important to be able to identify and isolate the different areas/steps that make up your eCommerce operation, as this will help you better understand where your blockers lie and create strategies for continuous improvement. Today we want to focus on warehouse vs inventory management, as those will make a big chunk of your overall business management.

While inventory management involves maintaining optimal stock levels, minimizing holding costs, and preventing stockouts or overstock situations, warehouse management focuses on the physical storage, organization, and movement of inventory within the fulfilment centre or warehouse facility. Together, these functions form the backbone of eCommerce logistics, dictating the speed and accuracy of order fulfilment, which directly impacts customer satisfaction and retention.

By understanding the key differences between inventory and warehouse management, businesses can streamline their logistics processes, optimize inventory levels, and enhance operational efficiency. Whether you’re a seasoned eCommerce entrepreneur or just embarking on your journey, gaining insights into these fundamental aspects of logistics management is essential for navigating the competitive landscape and achieving sustainable growth. So, let’s get into it.

What is inventory management?

Inventory management is the beating heart of any eCommerce operation, ensuring the smooth flow of goods from supplier to customer. At its core, inventory management involves the processes and systems used to oversee and control the movement of goods within a business. It involves tracking stock levels, replenishing inventory, and strategically allocating resources to meet customer demand. For eCommerce businesses, where the virtual shelves never close, effective inventory management is crucial for maintaining customer satisfaction, streamlining operations, and maximizing profitability.

Goals and benefits of inventory management

The primary objectives of inventory management are varied, reflecting the intricate balance between supply and demand in the eCommerce ecosystem. One key goal is to optimize stock levels, striking a delicate equilibrium between excess inventory and stockouts. By accurately forecasting demand and adjusting inventory levels accordingly, businesses can minimize excess inventory costs while ensuring they have enough stock on hand to fulfil customer orders promptly. Additionally, inventory management aims to reduce carrying costs associated with holding excess inventory, such as storage fees and depreciation, improving overall financial performance.

Inventory management techniques

To achieve these objectives, eCommerce businesses employ a variety of inventory management techniques and strategies tailored to their unique needs and challenges. These may include Just-in-Time (JIT) inventory management, where inventory is ordered and received just in time to fulfil customer orders, minimizing holding costs and maximizing efficiency. Other strategies, such as ABC analysis, prioritize inventory based on its value and demand, allowing businesses to allocate resources more effectively. Additionally, inventory management systems (IMS) and software solutions, like Despatch Cloud, provide advanced features for tracking inventory levels, automating reorder processes, and generating insightful reports to inform strategic decision-making.

What is warehouse management?

Warehouse management is the cornerstone of efficient order fulfilment and customer satisfaction. In essence, it encompasses the strategic planning, execution, and optimization of all activities within a warehouse or distribution centre. Its primary objective is to ensure that goods are stored, organized, and processed in a manner that maximizes efficiency and minimizes costs. In the dynamic landscape of eCommerce, where speed and accuracy are becoming the standard, effective warehouse management is essential for maintaining a competitive edge and meeting the evolving needs of customers.

What does warehouse management involve?

The key functions of warehouse management revolve around the efficient handling of inventory throughout its lifecycle within the warehouse. This includes tasks such as inventory storage, where goods are strategically allocated to specific locations within the warehouse based on factors like demand, accessibility, and storage requirements. Additionally, warehouse management encompasses picking (the process of retrieving items from storage locations to fulfil customer orders), as well as packing and shipping, where orders are prepared for dispatch and sent to customers in a timely manner. Each of these functions plays a crucial role in ensuring smooth warehouse operations and seamless order fulfilment.

Benefits of warehouse management

Efficient warehouse operations are essential for meeting customer demands and delivering exceptional service in the competitive eCommerce landscape. Timely order fulfilment is a key driver of customer satisfaction, and the role of efficient warehouse management in achieving this goal cannot be understated. By optimizing inventory storage, streamlining picking and packing processes, and minimizing order processing times, eCommerce businesses can ensure that orders are fulfilled accurately and promptly, leading to improved customer experiences and long-term loyalty.

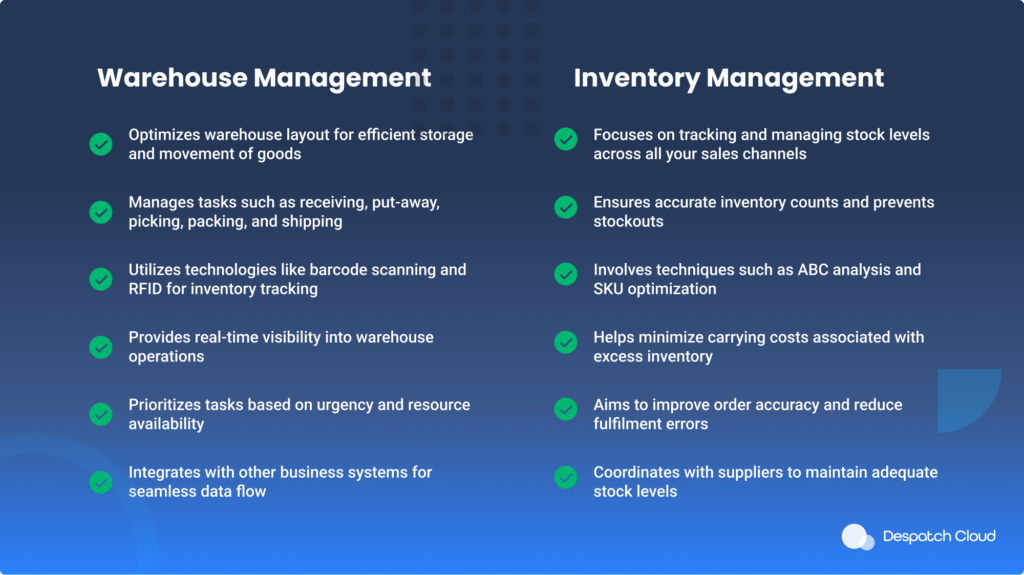

Key differences between inventory management and warehouse management

Inventory management and warehouse management are two critical components of logistics management in eCommerce operations, each serving distinct yet interconnected purposes.

Inventory management primarily focuses on overseeing the flow of goods within a business. It involves tracking and controlling inventory levels, optimizing stock quantities, and ensuring efficient utilization of resources. The primary objective of inventory management is to strike a balance between supply and demand, minimizing stockouts while avoiding overstock situations that can lead to unnecessary carrying costs and obsolescence. Essentially, inventory management is concerned with maintaining accurate stock records, forecasting demand, and aligning inventory levels with customer needs.

On the other hand, warehouse management involves the physical storage and handling of goods within a warehouse or distribution centre. It involves the day-to-day operations of managing inventory, including receiving, storing, picking, packing, and shipping goods to fulfil customer orders.

While inventory management focuses on the broader strategic aspects of inventory control, warehouse management deals with the tactical execution of these strategies within the warehouse environment. The primary functions of warehouse management include optimizing warehouse layout and design, implementing efficient storage systems, and streamlining order fulfilment processes to ensure timely and accurate order processing.

Despite their interconnectedness, inventory management and warehouse management present distinct responsibilities and challenges. Inventory management requires meticulous record-keeping, data analysis, and forecasting to anticipate demand and maintain optimal stock levels. In contrast, warehouse management involves physical tasks such as organizing inventory, managing warehouse space, and coordinating logistics operations to ensure smooth and efficient warehouse operations. While inventory management focuses on strategic planning and decision-making, warehouse management requires hands-on coordination and execution to meet the demands of eCommerce fulfilment. Balancing these responsibilities effectively is essential for businesses to optimize their logistics operations and deliver exceptional customer experiences.

The integration of inventory and warehouse management solutions

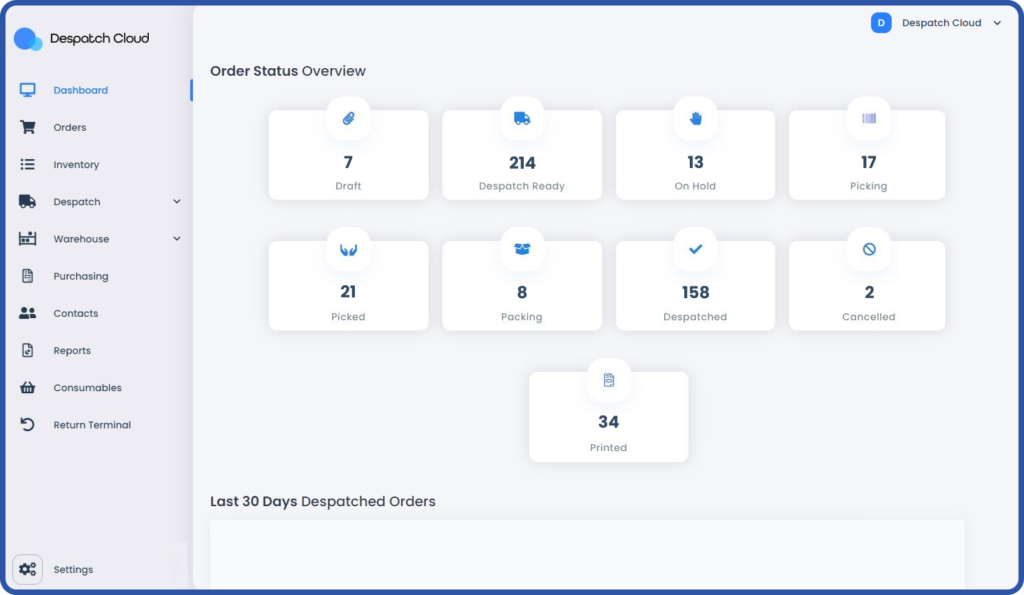

Despatch Cloud seamlessly integrates inventory and warehouse management functions within its software, offering a comprehensive and robust solution for eCommerce businesses. By consolidating these capabilities, Despatch Cloud streamlines operations, enhances efficiency, and improves overall productivity.

Key features include the ability to provide real-time visibility into inventory levels across all channels and warehouses. This ensures that businesses have accurate and up-to-date information about their stock, enabling them to make informed decisions and prevent stockouts or overstock situations. Additionally, Despatch Cloud automates inventory tracking and management processes, reducing the need for manual intervention and minimizing the risk of errors.

As a warehouse management software, it optimizes warehouse operations by enabling businesses to efficiently manage picking, packing, and shipping processes. The software includes features such as barcode scanning, order prioritization, and task automation, allowing businesses to fulfil orders quickly and accurately. By streamlining these processes, Despatch Cloud helps businesses improve order fulfilment times and enhance customer satisfaction.