In this guide, we’ll go over everything you need to know about warehouse management systems, along with a list of the top WMS providers out there.

Efficient warehouse management is a crucial element of any sucessful eCommerce and retail operation. A robust WMS system can optimise warehouse processes, speed up order fulfilment, and simplify inventory management, ensuring businesses meet customer demand while maximising operational efficiency. In this guide, we’ll go over everything you need to know about warehouse management systems, along with a list of the top WMS providers out there. Let’s get into it!

Now, let’s look at some of the top warehouse management system vendors that businesses should consider in 2024. These vendors provide cutting-edge solutions, competitive features, and customisation options, catering to the diverse needs of retailers, warehouses and distribution centres:

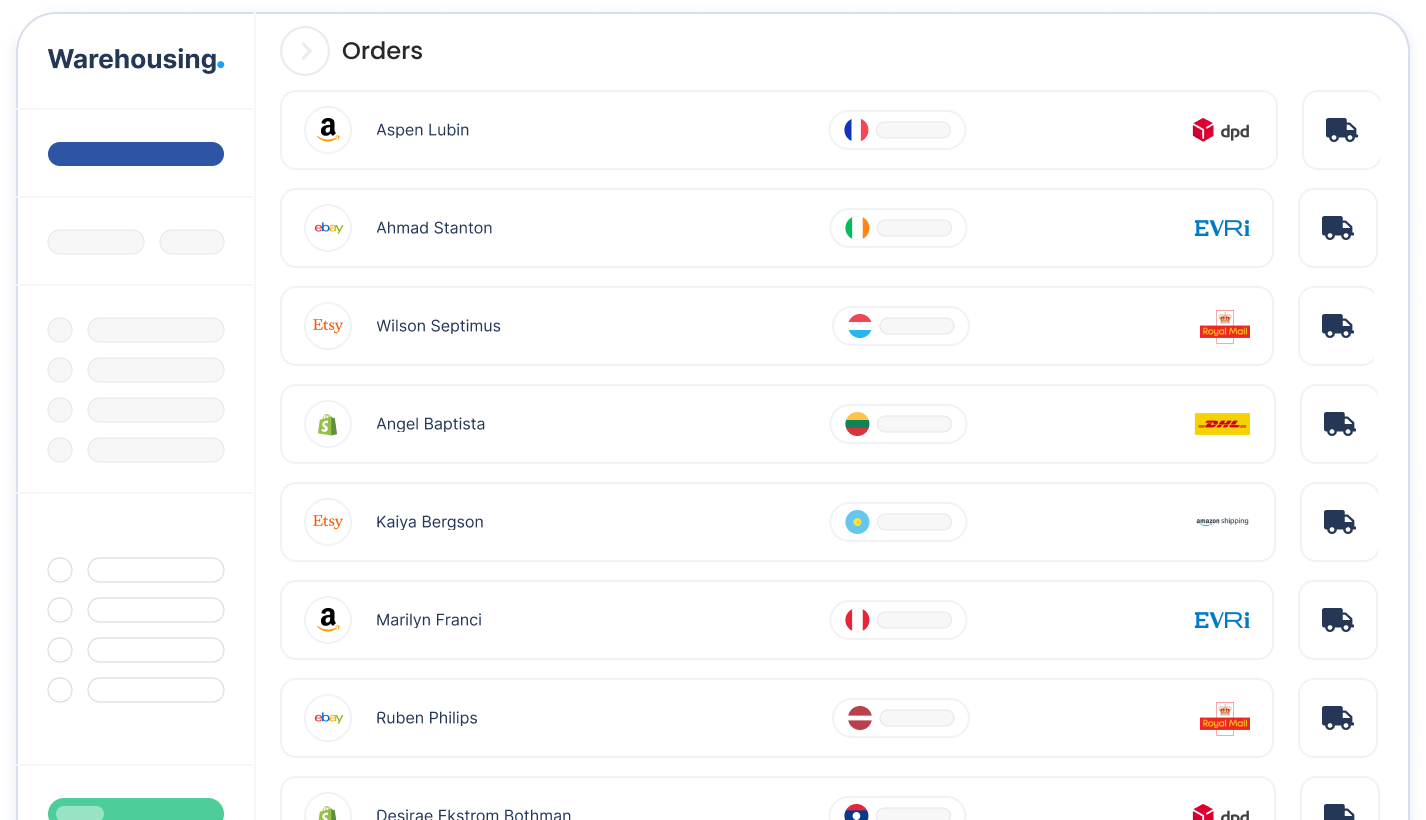

Armed with cutting-edge technologies, Despatch Cloud Warehousing is an advanced warehouse management system (WMS) designed specifically for eCommerce businesses looking to streamline and scale their post-purchase and integrate with more platforms and systems.

Key features include instant connection and real-time syncing with 80+ eCommerce platforms and 160+ couriers around the globe from one central hub, a scanning app accessible from any Android device, a dedicated returns portal, and a built-in email template builder for timely, on-brand customer communications.

Mintsoft provides a unified platform for selling, fulfilling and despatching orders. Their software offers powerful order, inventory and warehouse management solutions for fulfilment businesses and online retailers, along with extensive integration capabilities, including 89+ couriers and 67+ online shopping platforms.

Check out their website to learn more.

Brightpearl is a retail operating system that helps businesses automate operations and plan their inventory more efficiently.

Top features include inventory planning, multichannel order and stock management, a retail-focused CRM and a POS system, helping you sync your online and offline channels in real time. They also offer full training of your team, as a standard part of the onboarding process.

Check out their website to learn more.

A renowned, UK-based WMS software provider, Peoplevox specialises in tailored solutions for larger retailers with intricate warehouses. Their focus lies in omnichannel retail, delivering personalised solutions seamlessly integrated across diverse systems.

Check out their website to learn more.

Boxwise is a Warehouse Management System designed for easy integration with your ERP, such as Exact Globe or AFAS Profit. This system enables your warehouse staff to handle tasks like picking, packing, and scanning with confidence. It ensures that your deliveries reach customers on time and in full.

Check out their website to learn more.

ShipHero’s Warehouse Management System streamlines warehouse operations, making picking, packing, and shipping hassle-free. Their WMS integrates seamlessly with top eCommerce systems, helping you save time and costs while boosting customer satisfaction. ShipHero offers three subscription plans: ShipHero Standard, ShipHero 3PL, and ShipHero Enterprise.

Check out their website to learn more.

A global organization with vast supply chain experience, SAP provides a Warehouse Management System (WMS) as part of its comprehensive ERP software. This dynamic and flexible solution focuses on essential dashboards and built-in KPIs for efficient warehouse management.

Check out their website to learn more.

An American software company, BlueYonder stand as a leader in the 2022 Gartner Magic Quadrant for Warehouse Management Systems. They offer a global supply-chain operating system, helping automotive and industrial customers transform their planning, scheduling and production capabilities.

Check out their website to learn more.

Market leader in the 2023 Gartner Magic Quadrant for Warehouse Management Systems, Oracle’s Warehouse Management solution enables users to combine the benefits of the cloud with warehouse management functionality. Key features and offerings include support for omnichannel fulfilment, as well as end-to-end inventory management, from manufacturer to distribution centre and from store to consumer.

Check out their website to learn more.

Centric WMS is a versatile solution designed to enhance logistics efficiency. Regardless of your industry or company size, Centric WMS offers comprehensive tools to optimise goods flows and boost warehouse capacity. It empowers users to take control of their logistics performance with a reliable and adaptable system that caters to diverse business needs.

Check out their website to learn more.

Boltrics offers powerful software for logistics service providers. With extensive industry experience, they lead the market in Transport and Warehouse Management, Freight Forwarding, Finance, and ERP. From scanning and setting up connections with external platforms to billing and contracting, they have got you covered.

Check out their website to learn more.

Manhattan is best known for its supply chain and omnichannel eCommerce solutions, which combine information from across the entire organisation. Their WMS is customised and used by major players like Argos, Crocs, and Scotch and Soda.

Check out their website to learn more.

Oracle was also named a market leader in the 2022 Gartner Magic Quadrant for Warehouse Management Systems. Their Warehouse Management solution makes it easy to combine the benefits of the cloud with warehouse management functionality.

Check out their website to learn more.

ShipBob offers best-in-class supply chain and fulfillment capabilities for thousands of brands. ShipBob has an international fulfillment network across the US, Canada, UK, EU, and Australia. ShipBob’s proprietary technology combines order and inventory management, warehouse management, predictive data and analytics, as well as optimized shipping for eCommerce companies.

Check out their website to learn more.

Orderwise is a comprehensive ERP solution that provides wholesalers, distributors, retailers and manufacturers with a powerful platform for growth. Stock-focused businesses throughout the UK implement the software because it enables them to bring their teams, data and technology together to automate order management, stock management, warehouse management, eCommerce, point of sale, business intelligence, transport management, financials and more.

Check out their website to learn more.

Clarus WMS is a leading warehouse management software designed to bring Tier 1 features to businesses of all sizes, making advanced warehouse automation more accessible and affordable. Developed in collaboration with top supply chain and logistics companies, Clarus WMS offers a powerful yet intuitive platform that streamlines operations, boosts productivity, and eliminates the need for extensive training.

Check out their website to learn more.

“Finding the Warehousing software that can cope with the complexities of our business, all the different marketplaces, couriers and bringing them all together in an efficient way has been invaluable for our business and Despatch Cloud has helped us achieve that.”

John Stone

ShadowFoam – Managing Director

A warehouse management system is a software application or platform designed to support and optimise warehouse operations. It provides comprehensive visibility, automation, and control over key aspects of warehouse management, such as inventory tracking, order processing, picking, packing, and shipping.

In the dynamic and rapidly evolving eCommerce landscape, efficient warehouse management is essential for meeting customer expectations and securing a competitive edge. A warehouse management system plays a vital role in ensuring smooth order fulfilment, accurate inventory management, and timely shipment processes. By leveraging a WMS system, distributors and retailers can efficiently manage picking, packing, and shipment processes, providing customers with a seamless post-purchase experience.

Warehouse management systems also offer advanced functionality to aid in stock management, replenishment, and returns, enabling businesses to adapt to market conditions and customer demand. With real-time visibility into inventory levels, businesses can make data-driven decisions, ensuring optimal stock levels, reducing carrying costs, and minimising stockouts.

Warehouse management systems have come a long way since their first introduction to the market, evolving to meet the ever-changing needs of modern supply chain operations.

In the past, warehouse management was primarily manual, with basic systems focusing on storage management and order tracking. However, with the advent of technology, WMS systems now integrate IT systems, logistics processes, and warehouse operations, revolutionising the way warehouses are managed.

Over the years, WMS systems have developed sophisticated features and functionalities to optimise warehouse operations. The historical development of warehouse management systems brought about advancements such as machine learning, automation, and voice-picking technology, improving operational efficiency, and reducing labour costs.

Today, warehouse management systems have gone beyond basic inventory control and order management, integrating with enterprise resource planning (ERP) systems to provide a holistic approach to warehouse operations. The latest WMS solutions also leverage cloud-based platforms, enabling businesses to access real-time data and enhance operational efficiency. These cloud-based systems offer flexibility, scalability, and accessibility, making them an emerging trend in warehouse management.

With the evolution of warehouse management systems, functionality has expanded to include dock management, yard management, labour management, transportation management, and more, catering to the diverse needs of warehouses and distribution centres of all sizes. The primary focus of WMS systems in recent years has been on meeting the demands of larger enterprises, ensuring the right products reach the right customers at the right time and right place.

Now, let’s explore the different types of warehouse management systems that are prevalent in 2024. Warehouse management systems can be broadly categorised into 3 types: standalone WMS, integrated WMS, and cloud-based WMS. Each type has its own set of advantages and considerations, catering to the specific needs and constraints of different businesses.

Standalone WMS systems are independent software applications specifically designed for warehouse management. They offer basic functionality and are generally more cost-effective, making them an ideal choice for smaller warehouses. However, standalone WMS systems may lack the extensive functionality and scalability of integrated systems, limiting their suitability for larger enterprises.

Pros of Standalone WMS:

Cons of Standalone WMS:

Integrated WMS solutions, on the other hand, offer a seamless integration with other software systems, such as enterprise resource planning (ERP) systems. This integration enables efficient data exchange, real-time visibility, and automation, optimising warehouse processes and enhancing operational efficiency. While integrated WMS systems provide extensive functionality, they may require higher investment and customisation. However, for larger enterprises with complex warehouse operations, integrated WMS systems provide a comprehensive solution.

Pros of Integrated WMS:

Cons of Integrated WMS:

Cloud-based warehouse management systems have emerged as a popular trend in 2024. These systems offer the flexibility, scalability, and accessibility required by modern businesses. By leveraging cloud technology, businesses can access real-time data, collaborate across locations, and optimise warehouse processes without the need for extensive IT infrastructure. Cloud-based WMS solutions provide convenience, cost-effectiveness, and operational efficiency, making them highly desirable for businesses looking to streamline their warehouse operations.

Advantages of cloud-based WMS:

Key Features of cloud-based WMS:

A well-designed and effective WMS solution can unlock numerous advantages, improving order fulfilment, inventory management, and overall customer satisfaction.

A WMS system provides businesses with valuable insights into warehouse operations, inventory management, and order fulfilment processes. By leveraging this data, businesses can make informed decisions to reduce labour costs, improve inventory control, and optimise order-picking processes.

With a WMS system in place, businesses can expedite their order fulfilment processes, ensuring efficient picking, packing, and shipment processes. By automating repetitive tasks and streamlining warehouse operations, WMS systems enhance order fulfilment speed and accuracy, leading to improved customer satisfaction. With faster order processing, businesses can meet customer demand and maintain a competitive edge in the eCommerce and retail market.

Implementing a warehouse management system can result in significant cost savings and error reduction. WMS systems optimise inventory management, reducing carrying costs and minimising errors caused by manual processes. The automation and visibility provided by WMS solutions ensure accuracy, reducing the risk of errors in order fulfilment, inventory management, and shipping processes. It also helps improve productivity in your warehouse, reducing labour costs.

Deciding when to implement a Warehouse Management System (WMS) can be crucial for the growth and efficiency of your business. Whether you’re running a small warehouse or managing a large distribution center, the signs that it’s time to upgrade to a WMS often become clear through a few key indicators:

1. Rapid Growth

If your business is expanding quickly, and manual processes are becoming overwhelming, a WMS can streamline operations and help you scale efficiently. When orders start piling up, and you struggle to keep up with fulfillment, a WMS will automate processes and reduce errors.

2. Inventory Errors and Losses

Frequent mistakes in inventory counts or misplaced products are red flags. A WMS provides real-time visibility into your stock, eliminating manual tracking and reducing costly errors.

3. Difficulty Managing Orders Across Channels

With the rise of eCommerce, businesses are dealing with orders from multiple sales channels. A WMS integrates seamlessly with your platforms, ensuring inventory is updated across all channels in real-time, preventing overselling or stockouts.

4. Lack of Visibility and Reporting

If you’re struggling to get a clear picture of what’s happening in your warehouse, from stock levels to staff productivity, a WMS can provide detailed reports and analytics. This visibility is critical for decision-making and forecasting.

5. Customer Complaints and Delayed Shipments

Slow fulfilment, incorrect shipments, and rising customer complaints are telltale signs. A WMS improves order accuracy and speeds up the fulfillment process, leading to better customer satisfaction.

If your business is experiencing any of these challenges, it’s a strong indication that it’s time to invest in a WMS. The right system can not only save time and reduce costs but also give you the control and insight needed to optimize your entire warehouse operation.

There are several key elements to keep in mind when choosing the right warehousing solution for your business.

Our experience with our own test-bed warehouse facility as well as working with eCommerce businesses of all industries and sizes has allowed us to identify the following general considerations:

If you’re not ready to fully implement a Warehouse Management System (WMS) but still need to manage your warehouse operations effectively, there are several alternatives you can explore. These options may offer a temporary solution, but they typically don’t provide the long-term scalability and efficiency that a full WMS delivers.

Manual Processes & Spreadsheets

Many smaller warehouses start by managing their operations manually or with basic tools like Excel spreadsheets. This option is inexpensive and easy to implement, but it can quickly become inefficient as your business grows. Manual tracking of inventory, orders, and shipments is prone to human error and doesn’t scale well with increasing complexity.

Inventory Management Software

While not as comprehensive as a WMS, standalone inventory management software can help you keep track of stock levels, product locations, and order fulfilment. These systems are usually easier to set up and less expensive, making them a good starting point for smaller businesses. However, they often lack the more advanced features of a WMS, such as real-time tracking and automation of warehouse tasks.

Enterprise Resource Planning (ERP) Systems

Some businesses manage their warehouse operations through an ERP system, which offers broader functionality across multiple business areas like finance, procurement, and supply chain management. While ERP systems can handle basic warehouse functions, they lack the specialisation and depth of a dedicated WMS. For larger operations or those with complex needs, a WMS is a more robust solution for warehouse-specific tasks.

Order Management Software

Order management systems (OMS) focus on tracking sales orders and ensuring they are fulfilled. This software is beneficial for businesses dealing with eCommerce or high-volume sales but doesn’t provide the comprehensive warehouse functionality that a WMS offers. It can, however, serve as a bridge between manual processes and a full-fledged WMS by improving order accuracy and inventory visibility.

Outsourcing Warehousing to 3PL Providers

Another alternative to implementing a WMS is outsourcing your warehousing and fulfilment operations to a third-party logistics (3PL) provider. These companies often use advanced WMS software themselves, so you benefit from the technology without needing to implement it. However, outsourcing means giving up control over certain aspects of your operations, which may not suit every business.

While these alternatives can serve as temporary solutions, they often fall short in terms of scalability, automation, and overall efficiency. As your business grows and operational demands increase, a dedicated WMS like Despatch Cloud will provide the robust functionality needed to streamline and optimise your warehouse for long-term success.

The timeline for implementing a Warehouse Management System (WMS) can vary depending on several factors, but typically it ranges from a few weeks to several months. Here’s what influences the duration:

Warehouse Size and Complexity

The larger and more complex your warehouse operation, the longer the implementation may take. Multiple locations, high SKU counts, or intricate workflows often require more time for system configuration and testing.

Customisation Needs

If your business has specific requirements, such as integrating with other software platforms or custom workflows, these customisations can extend the implementation timeline. However, modern WMS solutions often come with built-in flexibility, reducing the need for extensive development.

Data Migration

Transferring data, such as inventory levels and product information, from legacy systems to your new WMS can be a time-consuming process. The accuracy and cleanliness of your existing data can also affect how smoothly this process goes.

Training and Change Management

The time it takes to train your staff on using the new WMS can vary. If the system is intuitive and user-friendly, like Despatch Cloud’s, training can be quick and seamless. However, getting your team fully onboard and comfortable with the new processes can take longer in some cases, especially if there’s significant resistance to change.

Testing and Fine-Tuning

Before going live, your WMS needs to be thoroughly tested to ensure it works as intended within your operations. This includes testing for accuracy, performance, and integration with other systems. Any necessary adjustments or fine-tuning could add to the timeline.

On average, small to mid-sized warehouses can implement a WMS in 6 to 12 weeks, while larger, more complex operations may take up to 6 months. With a platform like Despatch Cloud Warehousing, designed for quick deployment and ease of use, you can streamline the process and start seeing benefits sooner.

When considering the implementation of a Warehouse Management System (WMS), cost is a key factor that businesses must take into account. WMS software costs can vary widely depending on factors such as the size of your operation, the complexity of your workflows, and the features you require. Here’s a breakdown of the different types of costs associated with WMS software:

Upfront Licensing or Subscription Fees

WMS providers typically offer either a one-time licensing fee or a subscription-based model. Subscription models, which are usually cloud-based, often include access to the software, regular updates, and support services. Prices can range from a few hundred pounds per month for smaller systems to several thousand pounds for more advanced, feature-rich solutions.

Implementation Costs

The process of implementing a WMS involves system integration, data migration, and staff training. These costs can vary depending on how complex the implementation is and how much customisation is required for your specific warehouse operations. For smaller warehouses, implementation costs may be lower, but for larger or more complex operations, this can become a significant investment, potentially reaching tens of thousands of pounds.

Hardware Requirements

In addition to software costs, businesses will need to invest in hardware such as barcode scanners, mobile devices, printers, and potentially RFID systems. These tools are essential for maximising the efficiency of a WMS, enabling real-time tracking and automation of warehouse processes. Depending on the size of your warehouse and the amount of equipment needed, hardware investments can be a major cost consideration.

Maintenance and Support

Ongoing costs for maintenance and support services are also an important consideration. Subscription models often bundle these into the monthly fee, but if you’re using a licensed system, you may have to pay separately for support, upgrades, and troubleshooting, which can add to the long-term cost of running your WMS.

Ultimately, WMS software is a significant investment that should be evaluated based on its potential to optimise warehouse operations and improve efficiency in the long run. While the costs can be substantial, the return on investment often justifies the expense, especially for businesses looking to scale.

Choosing the right Warehouse Management System (WMS) is crucial for the success of any eCommerce or retail business. With the evolution of technology, WMSs have become more efficient and capable of meeting the demands of the industry, leveraging AI, automation and IoT to introduce new, powerful features and help businesses stay ahead in the competitive eCommerce landscape. Whether you opt for a standalone, integrated, or cloud-based system, the benefits of using a WMS are undeniable. It allows for data-driven decision-making, faster order fulfilment, and cost reduction. By implementing best practices such as efficient processes, barcode scanning, and data-driven inventory planning, businesses can optimise warehouse operations. Finally, keep an eye out for the top WMS vendors in 2024 to ensure access to the latest features and technological developments.

Check out this 3-minute demo of our Warehouse Management System. Discover essential features as Adam guides you through our user-friendly interface. Want a personalised tour of our product? You can book your free demo with one of our product specialists by clicking the button below:

Address: Unit 76, Kelleythorpe Industrial Estate Kelleythorpe, Driffield, YO25 9FQ

Telephone: +44 137 7455180 | Company Number: 09615192 | ICO Registration Number: A8116774 | VAT Number: 214577410